- Home

- Factory Tour

-

Raw material workshop

Raw material workshop -

We use high quality bearing steel approved by world's well-known bearing brands SKF and TIMKEN

We use high quality bearing steel approved by world's well-known bearing brands SKF and TIMKEN -

Carburized steel used for manufacturing bearings

Carburized steel used for manufacturing bearings

Shown here are our pit furnace for carburizing process, and imported Austrian AICHELIN salt bath quenching equipment for bainite and martensite hardening.

-

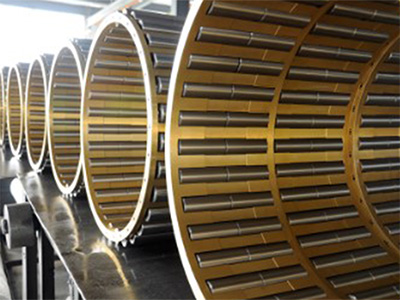

Grinding workshop

Grinding workshop -

Numerical Contntrol Grinder

Numerical Contntrol Grinder -

Numerical Contntrol Grinder

Numerical Contntrol Grinder

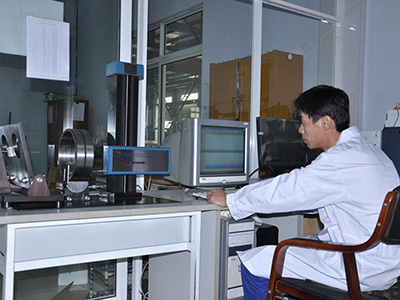

Our testing workshop is equipped with optical emission spectroscopy, Zeiss microscopy, Taylor Hobson profile projector and other testing equipment to ensure that bearings are made in accordance with customers’ requirements.

We have a testing and inspection line to accomplish strict quality control for finished products, ensuring that only the qualified products will be delivered to customers.

-

Ready-to-ship products zone

Ready-to-ship products zone -

Vacuum packaging of bearings

Vacuum packaging of bearings -

Protective packaging of tapered roller bearing, preventing damage to the ring and raceway

Protective packaging of tapered roller bearing, preventing damage to the ring and raceway

-

Pre-sales support

We provide customer services including technical consultation, helping customer select appropriate bearing and its steel material, optimizing bearing design, and offering flexible sales plan with reasonable solutions.

-

Sales support

We implement real-time tracking of your bearing order, complete procedures covering cold & hot processing technologies, quality control and inspection, quick delivery, application of certificates and freight documents.

-

After-sales support

We offer user manual of bearing installation, continue to follow up with bearing orders, feedback on customer problems and provide improvements, as well as respond quickly within 24 hours.

- Four Row Cylindrical Roller Bearings

- Four Row Tapered Roller Bearings

- Backup Bearings (Sendzimir Bearings)

- Cylindrical Roller Bearings

- Tapered Roller Bearings

- P&N Bearings for Continuous Casting Machines

- CARB Circular Roller Bearings

- Spherical Roller Bearings

- Deep Groove Ball Bearings

- Four Point Contact Ball Bearings

- Angular Contact Ball Bearings

- Spherical Roller Thrust Bearings

- Tapered Roller Thrust Bearings

- Screw Down Bearings

- Cylindrical Roller Thrust Bearings

- Slewing Bearings

- Spherical Plain Bearings

WZZZ Rolling Mill Bearings

WZZZ Rolling Mill Bearings- Plant: Wafangdian Zhengda Metallurgical Mill Bearing Co., Ltd.

- Exporter: Dalian Dragon Bearing Co., Ltd

- Add.: Lutun Village,Delisi Town, Wafangdian City, Liaoning Province

- Phone: +86-411-85327502

+86-411-85329002 - Contact: Andy Dou